As a vertically integrated manufacturer, Grand Seiko consistently pushes the envelope in all facets of watchmaking. Innovation has always been a fundamental part of the brand, informing groundbreaking leaps in all facets of horology, from the development of new movements to techniques in finishing, and more. The goal, of course, hasn’t changed since before the days that led to the first Grand Seiko timepiece in 1960: to produce the “ideal watch,” with a focus on precision, legibility, beauty, and durability.

Grand Seiko’s approach to metallurgy, or the science and technology of metals, has played an important role in executing these brand values. Using different materials, Grand Seiko has been and continues to be a pioneer in the field of metals, encompassing all parts of the watch.

At Watches & Wonders 2023, Grand Seiko unveiled five new references featuring cases made of Ever-Brilliant Steel, a special alloy making its way into the brand’s catalog. Today, we’ll take a closer look at this novel case and bracelet material and how it compares to the industry standard.

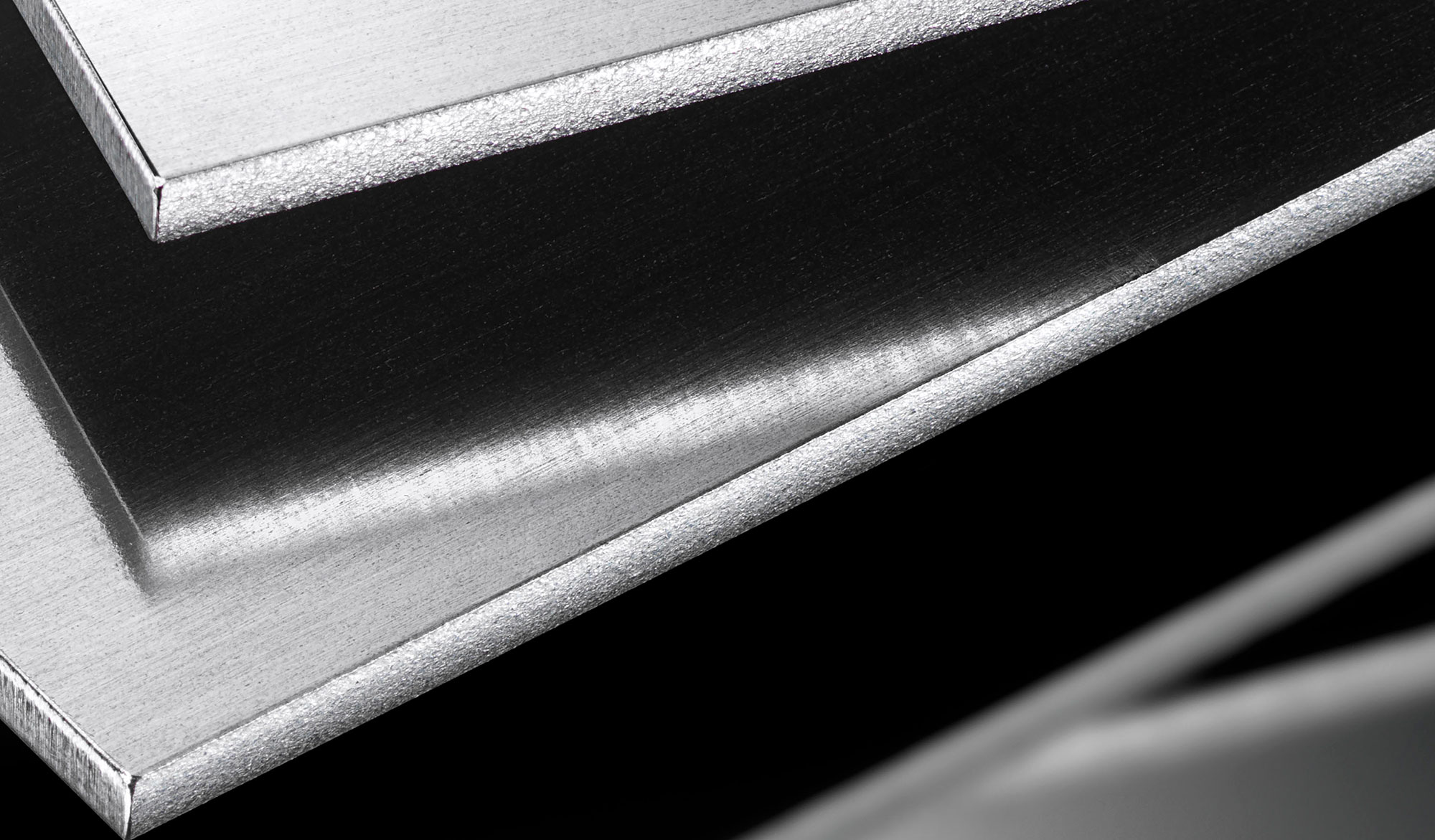

Stainless Steel

Most Grand Seiko watches today are made of stainless steel using an alloy that is generally considered standard across the high-end watch industry. With its high hardness, low carbon content, and antimagnetic properties, stainless steel is an excellent option for use in cases and bracelets. Additionally, it has notable anti-corrosive properties, which means it is an incredibly hard-wearing metal that can theoretically stand the test of time against pitting.

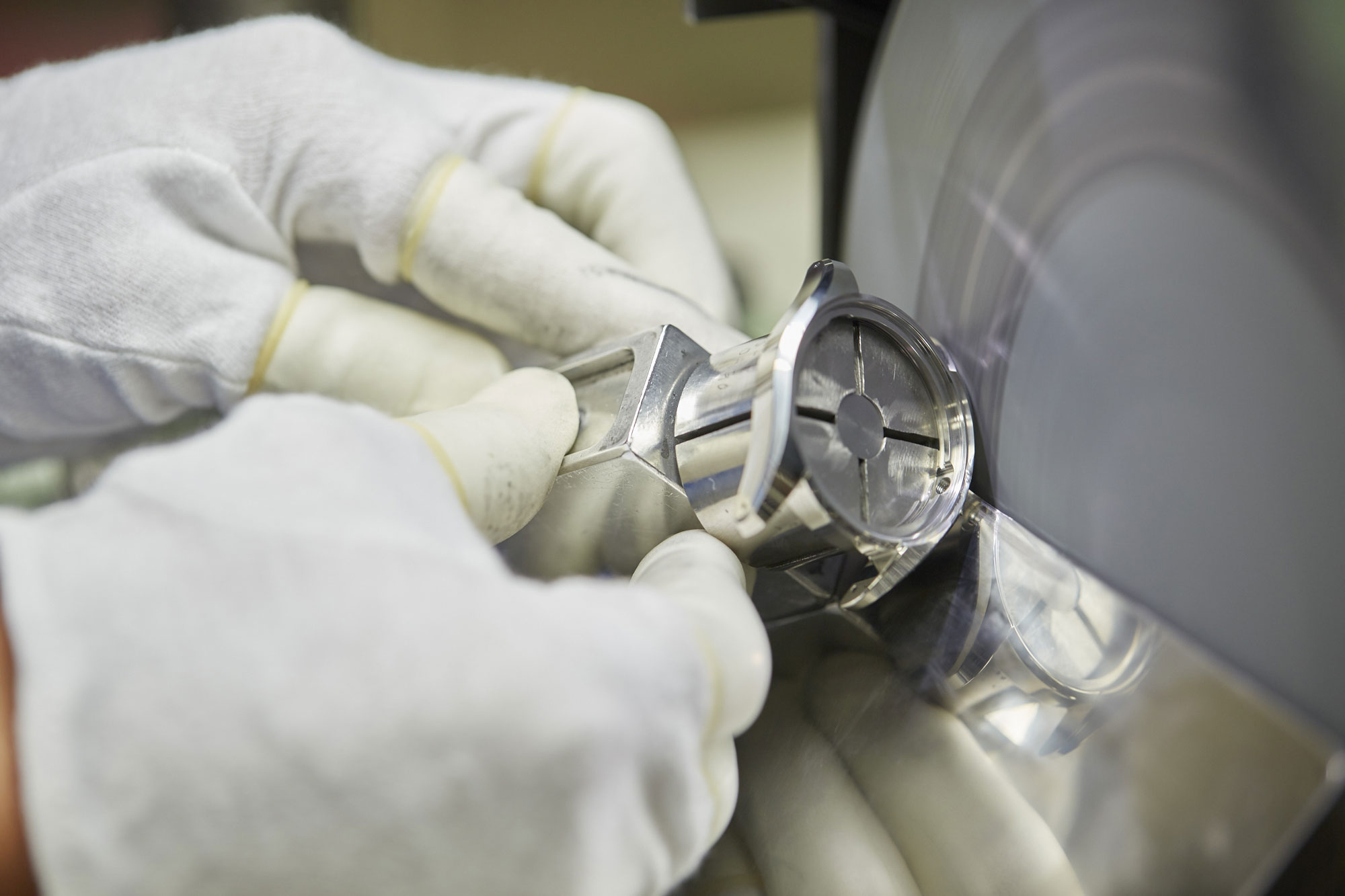

To make the most of the beauty of this metal, Grand Seiko applies a finishing known as Zaratsu. Named after the phonetic pronunciation of an old European machine called Sallaz, Zaratsu polishing is applied to all Grand Seiko cases, and it is instrumental in creating and defining the distinct Grand Seiko aesthetic defined by flat surfaces, sharp edges, and a distortion-free mirror finish. In short, Grand Seiko’s defining look is made possible through this markedly Japanese finishing technique.

Ever-Brilliant Steel: the world’s most corrosion-resistant stainless steel

A special alloy used in a handful of new Grand Seiko references, Ever-Brilliant Steel marks a notable leap in the brand’s pursuit of perfection. As one of the most corrosion-resistant stainless steel alloys, Ever-Brilliant Steel has a PREN (Pitting Resistance Equivalent Number) rating that is 1.7 times higher than that of stainless steel. With durability being one of Grand Seiko’s fundamental values, the development and use of this material further reassures the watch’s lasting beauty.

As the name suggests, Ever-Brilliant Steel has a brilliant white hue. When compared to Grand Seiko watches using standard stainless steel, watches made of Ever-Brilliant Steel will appear whiter along the hairline finished portions, giving the cases an immediately eye-catching appearance. Grand Seiko also Zaratsu polishes Ever-Brilliant steel, which is notably more difficult to finish to the brand’s exacting standards.

Currently, Ever-Brilliant steel is used across six regular production models in Grand Seiko’s collection. All feature Grand Seiko’s modern interpretation of the 44GS design, which is an excellent showcase for the intrinsic beauty of this alloy, made even more impressive through the high level of execution across the mirror-polished and hairline-finished surfaces.